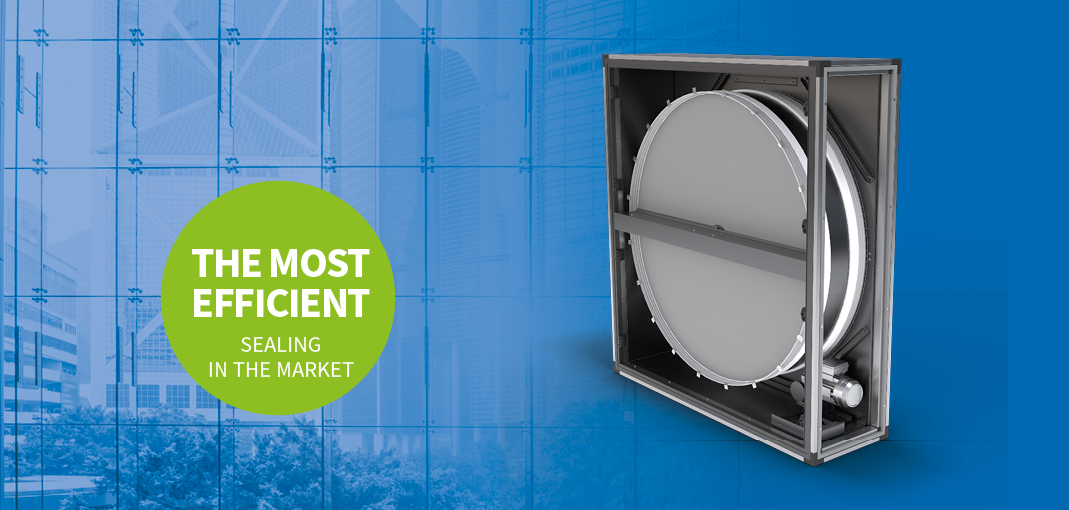

LABYRINTH SEALING

This solution considerably reduces the overall untightness of rotor, up to 1.5 % of air volume at maximum. Our special labyrinth sealing is the most efficient, fully functional sealing for rotary heat exchangers in the market.

In order to increase the tightness of the rotary heat exchanger, Kastt developed and patented a unique system of rotor sealing elements.

This solution considerably reduces the overall untightness of rotor, up to 1.5 % of air volume at maximum. Our special labyrinth sealing is the most efficient, fully functional sealing for rotary heat exchangers in the market.

The new sealing system significantly limits contamination of intake air and minimizes passive losses of intake and outtake air. While designing air-handling units, the need of energy to cover these losses is therefore considerably lower. Air-handling units with exchangers fitted with labyrinth sealing show the highest energy efficiency.

Main benefits

- Significant reduction of intake air contamination (EATR – Exhaust Air Transfer Ratio)

- Reduction of passive losses caused by untightness between intake and exhaust channel (OACF – Outdoor Air Correction Factor)

- Higher energy efficiency of air-handling units – lower specific power consumption of fans (SFP)

- Maintenance of maximum rotor efficient area for energy transmission

- Possible use in buildings with increased requirements for indoor environmental quality

- Long service life

Technical parameters

- Untightness ranges from 0.9 to 1.5 % of the nominal volumetric air flow rate (based on the results of tests pursuant to EN 308:1997 by the accredited testing laboratory at the Lucerne University of Applied Sciences and Arts).

- The labyrinth sealing system consists of two separate parts – a sealing along the rotor perimeter and a sealing in the dividing plane between the intake and exhaust air channels.

Do you like this product?

We will be happy to provide you with more information. Get in touch with us!

Other selected products

CLEANING DEVICE